Case Study: How a ship operator seeked to improved efficiency with TeamTec's Ejectors

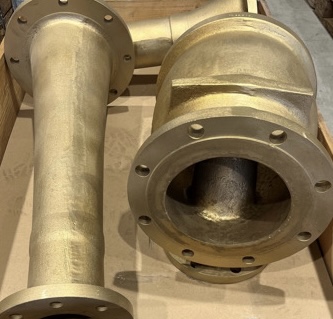

In the world of maritime engineering, every component of a vessel plays a crucial role in ensuring operational efficiency, reliability, and longevity. This was a reality faced by a global shipowner that approached TeamTec with a pressing issue: their cast steel ejector had deteriorated beyond repair (see picture after only eight (8) years of running-time), causing inefficiencies in their bilge pumping system. Seeking a long-term, cost-effective solution, they turned to TeamTec for guidance.

The challenge: A deteriorating cast steel ejector

Operating in harsh marine environments, the ship’s cast steel ejector had suffered extensive corrosion and erosion, leading to frequent maintenance stops and increased operational costs. The shipowner needed a replacement that would not only resolve the immediate issue but also deliver long-term benefits in terms of durability and efficiency.

The solution: Upgrading to high grade nickel-aluminium-bronze alloy (NAB) ejectors

After assessing the ship’s operational needs, TeamTec recommended replacing the cast steel ejector with a nickel-aluminium-bronze (NAB) ejector. This decision was based on key advantages of NAB ejectors according to the customer’s needs:

1. Superior corrosion resistance

High grade Nickel-aluminium-bronze alloy is highly resistant to seawater corrosion and cavitation, unlike cast steel, which is prone to rust and degradation. Given the ship’s exposure to salt-laden air and continuous seawater contact, the NAB ejector significantly reduced the risk of corrosion-related failures, ensuring a longer lifespan and fewer maintenance requirements.

2. High strength and durability

The mechanical properties of NAB provide exceptional strength and toughness, making it ideal for demanding maritime applications. Unlike cast steel, which can become brittle and crack under high stress, NAB ejectors maintain their structural integrity even in extreme conditions, reducing the likelihood of unexpected failures.

3. Compliance with environmental regulations

With tightening environmental regulations in the maritime industry, reducing waste and maintenance downtime has become a priority for shipowners. NAB ejectors contribute to sustainability by minimizing the need for replacements and reducing waste associated with corroded components, aligning with greener shipping initiatives.

Why more operators are switching to NAB Ejectors

The image on the right depicts a Nickel-Aluminium-Bronze (NAB) ejector that has been running for 29 years, only being removed for an extensive maintenance job on the ship. There was no need for any repairs on the ejector, belonging to another very satisfied customer.

This case underscores the advantages of upgrading to nickel-aluminium-bronze ejectors over traditional cast steel alternatives. With superior corrosion resistance, durability, and efficiency, NAB ejectors are becoming the preferred choice for shipbuilders and operators worldwide.

At TeamTec, we are committed to providing innovative and reliable solutions that enhance maritime operations. If your vessel is facing similar challenges with ejector performance, contact us today to explore how our NAB ejectors can improve efficiency and reduce lifecycle costs.

Get in touch with TeamTec today to learn more!

Email: ejectors@teamtec.no