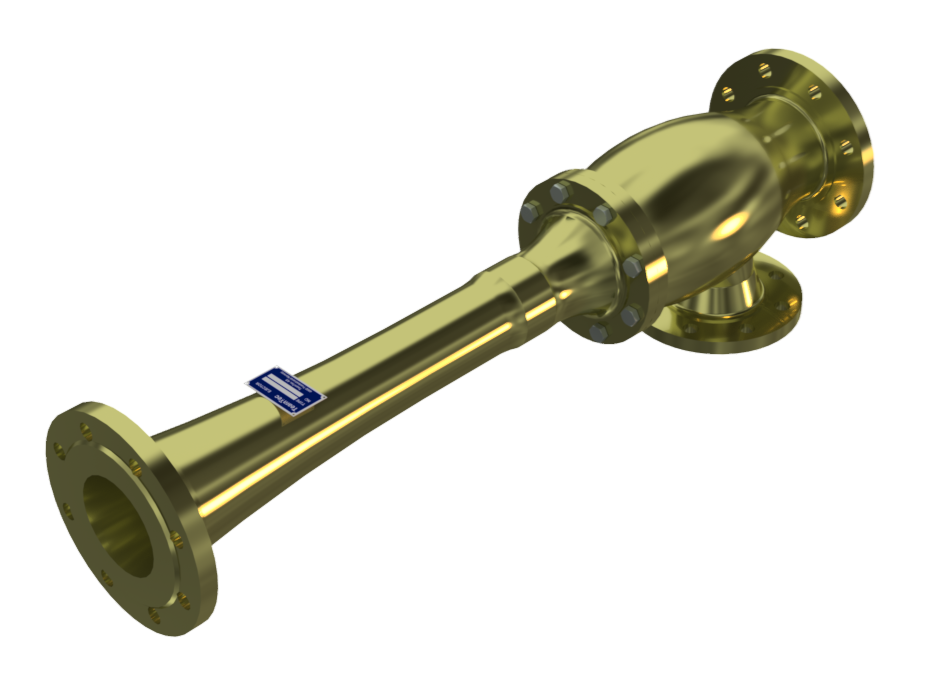

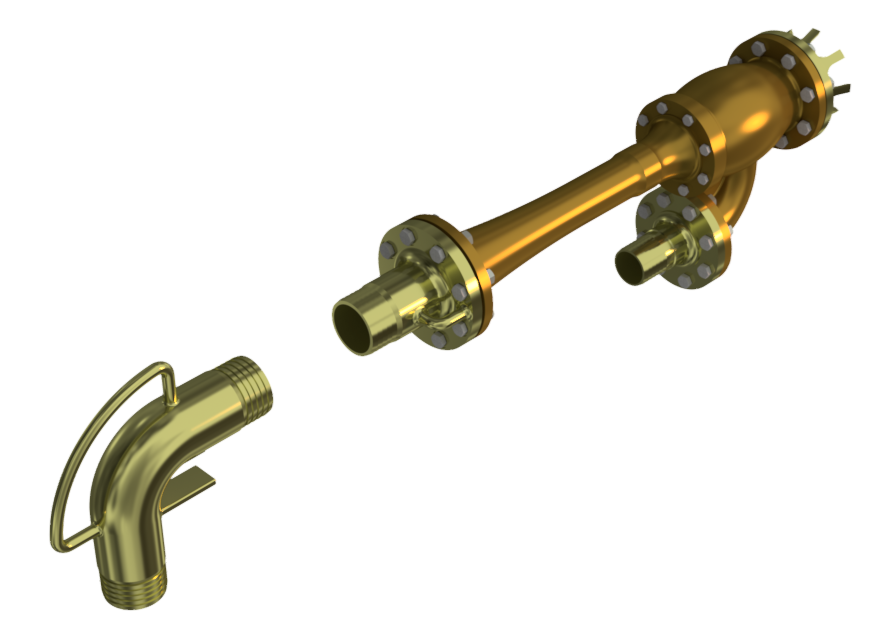

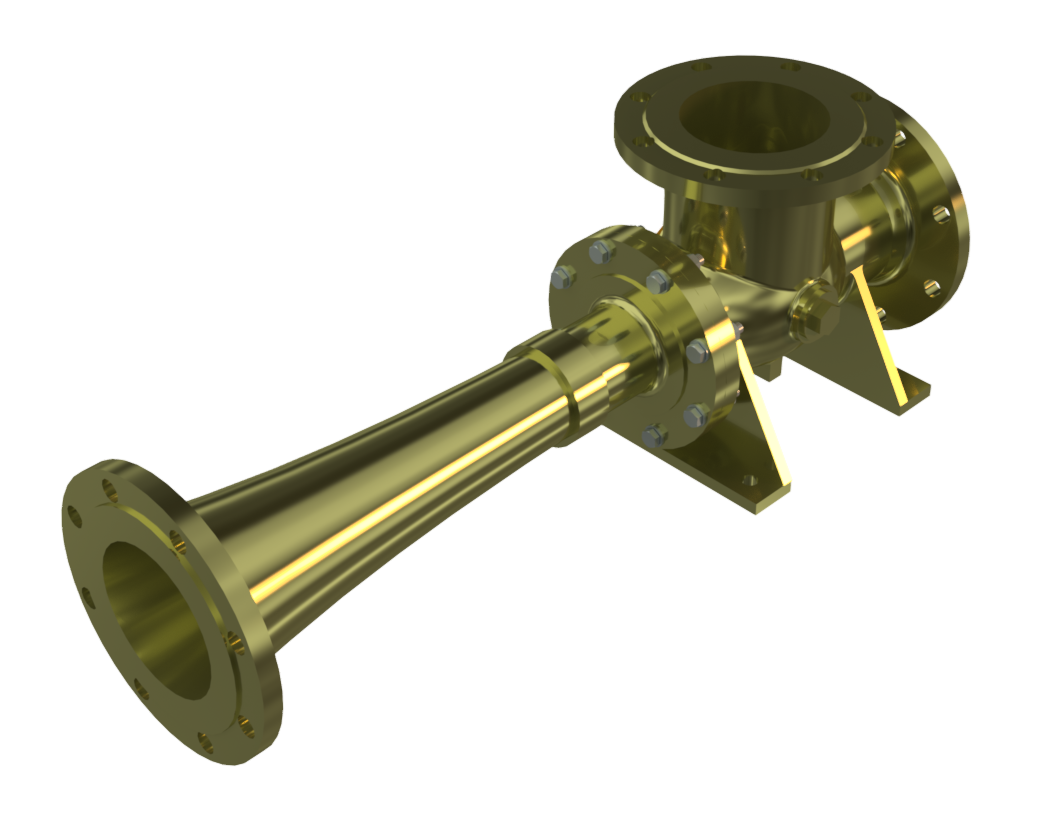

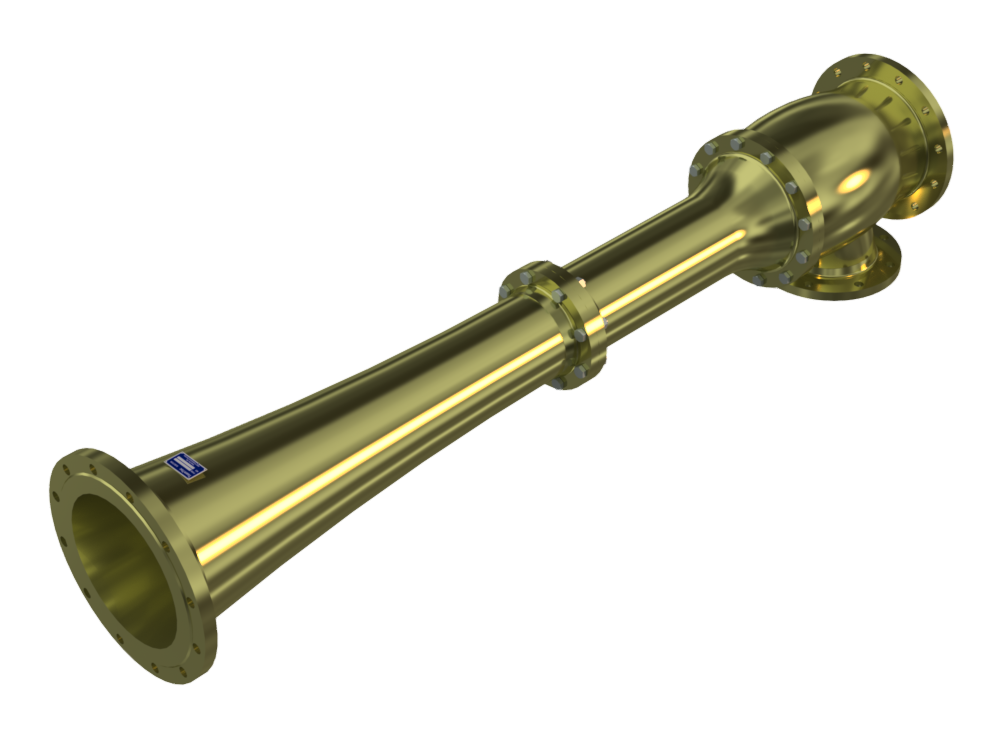

Stripping ejectors

For all-purpose,

ballast and cargo

oil stripping!

Stripping ejectors

- Downloads

- Stripping ejectors

Stripping ejectors

For all-purpose, ballast and cargo oil stripping.

TeamTec waste range of stripping ejectors from 1½-2-2½ to 16-16-20, with clearance from 9 mm to 89 mm.