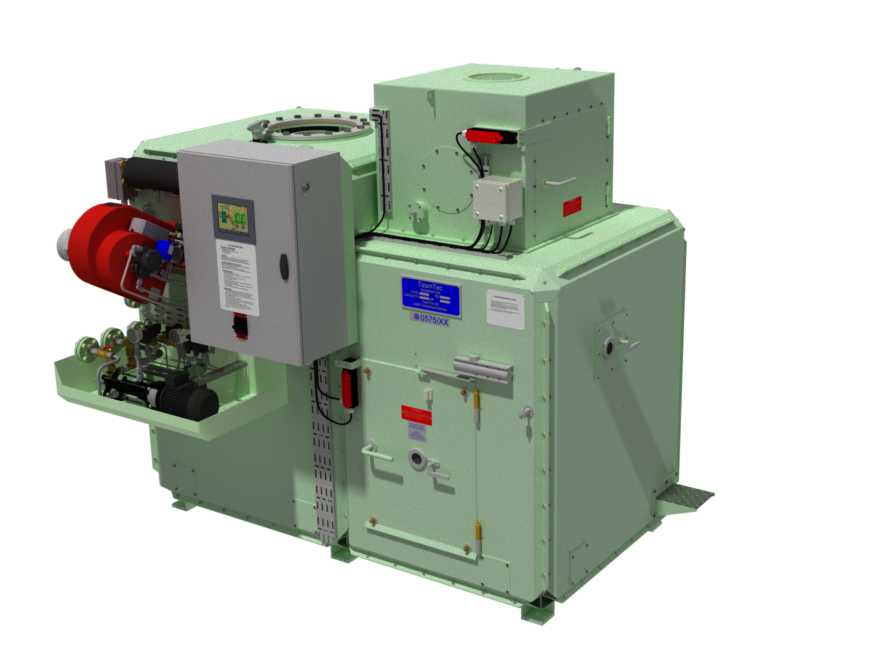

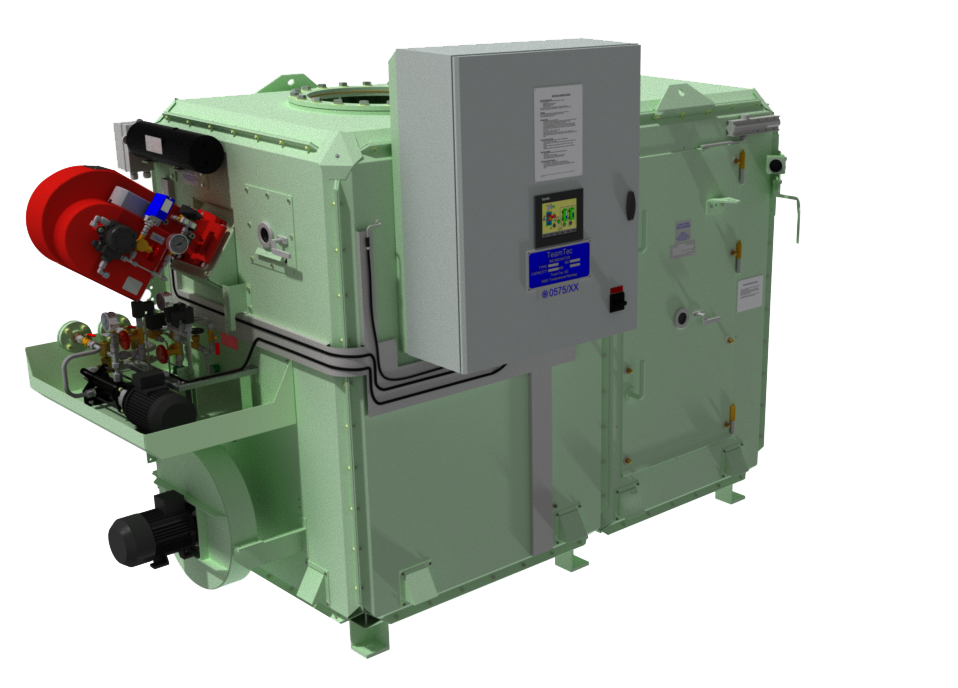

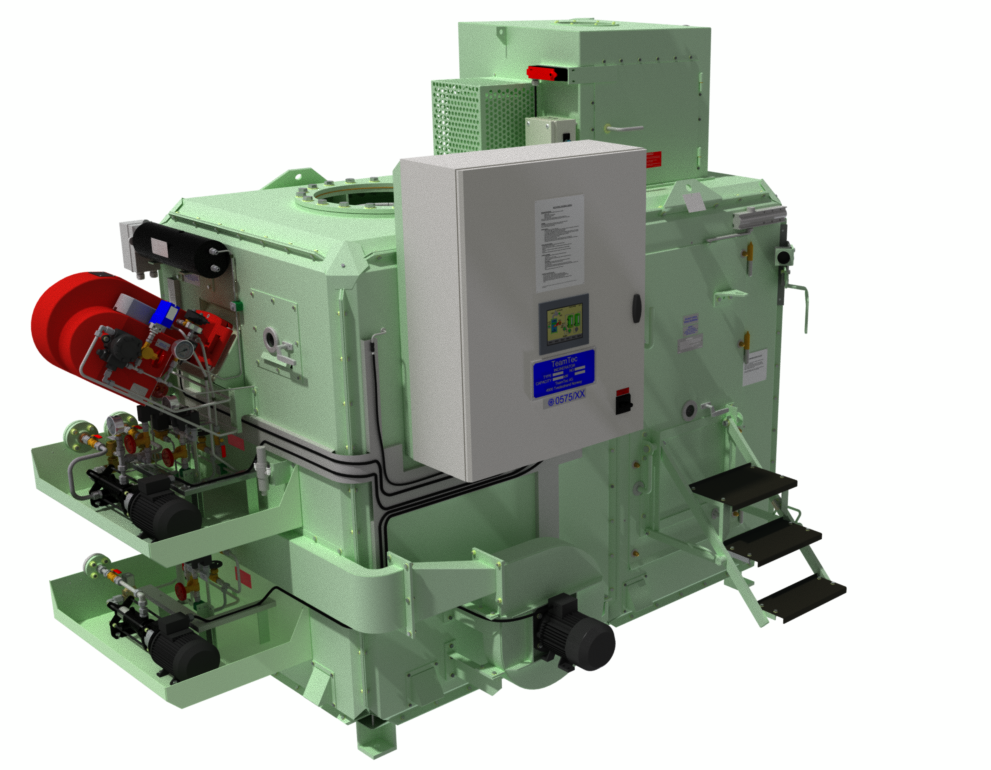

LOGI

Up till:

530kW

LOGI

- Downloads

- LOGI

LOGI

Our new incinerator model, Logi has some advantages compared to current design. The advantages are:

1.Lowering the threshold for integrating an incinerator in ship designs.

2.Significantly reduced weight and reduced footprint.

3.Optimized design.

4.Simpler and quicker operation and maintenance.

5.Invented for tomorrow’s requirements for a marine incinerator.

Summarized: Logi is a simplified, lighter, and smaller incinerator with competitive pricing.

Capacity:

•530 kW.

•Sludge: Approx. 69 liter sludge per hour at 25% water content.

•Solid waste, batch loading: 4 batches of 30 kg IMO waste in 7 hours possible due to quick cooling between each batch.

•Solid waste, sluice loading.